|

|

Post by stidrvr on Aug 19, 2009 22:54:12 GMT -7

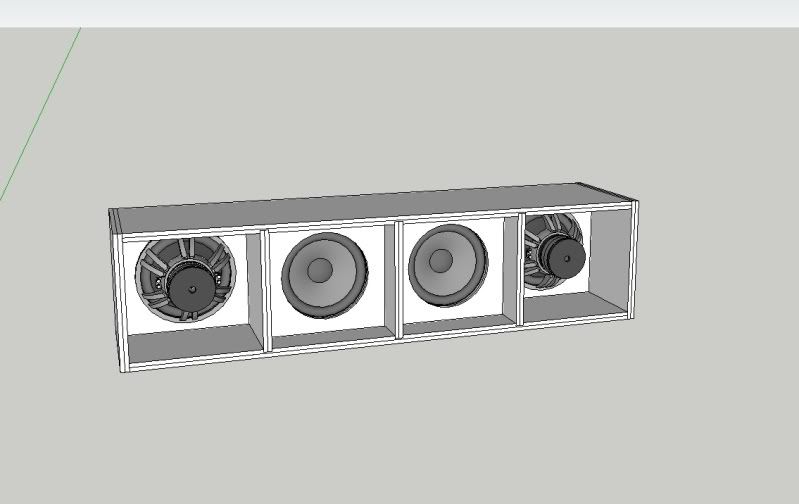

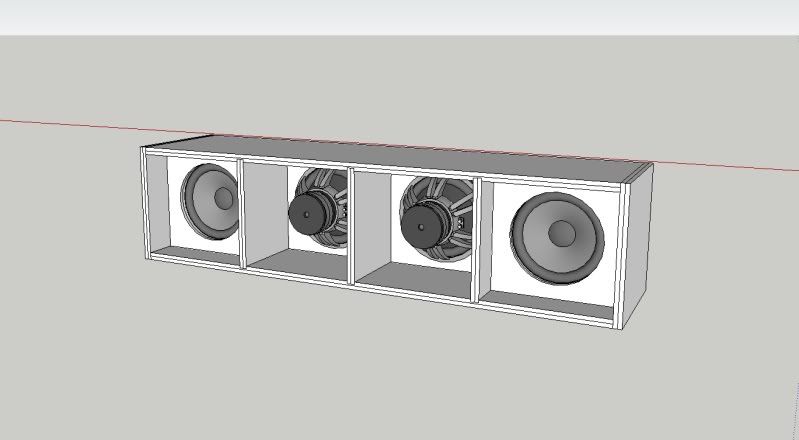

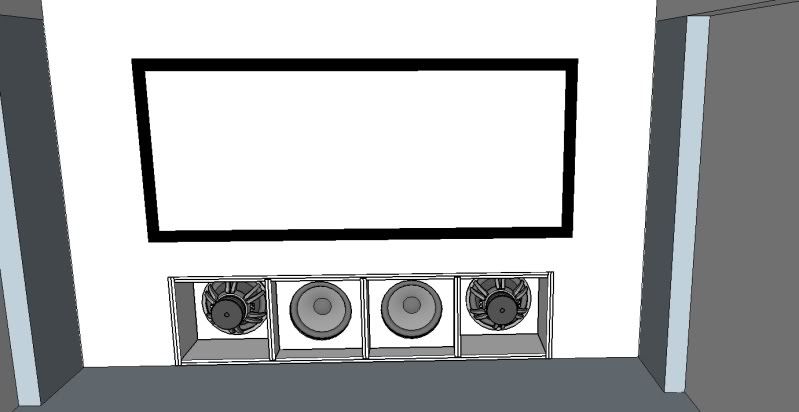

I made two manifolds but they may be interfering with the rest of the basement build. I came up with this line array setup in sketch-up. Knowing all of the problems with line arrays, I plan to over come this by bolting it to the concrete floor, and sealing with acoustic caulk. Plus that fact that its built out of laminated 3/4" mdf (1.5" total) for every piece, should minimize deflection. Thoughts? Drivers are FiCar IB18's with QSC RMX-2450. (drivers in pics are SDX15's scaled to 18's)    |

|

|

|

Post by ThomasW on Aug 20, 2009 6:45:45 GMT -7

Yes you can do that, but if that's the wall where the manifolds are mounted, you gain nothing by changing to a line array.

It would be handy to see pictures or at least a drawing of the current installation.

|

|

|

|

Post by stidrvr on Aug 20, 2009 7:42:51 GMT -7

Im not looking to gain anything in output. This is mainly for ease on the back side of the wall. Here are some other pictures:   The problem is is that theres a wall going up about 24 inches to the right of the sub on the far right. Not only that with the placement of the manifolds, as you come down stairs they are right there, and not easily hidden. |

|

|

|

Post by ThomasW on Aug 21, 2009 8:41:30 GMT -7

Ok that's makes sense.

The concept for the line array itself is fine. I'd beef up the wall itself since you have access to the backside. Line arrays are famous for causing the wall they're mounted on to shake.

|

|

|

|

Post by stidrvr on Aug 21, 2009 9:06:31 GMT -7

Right, thats why I was thinking of bolting it to the concrete, and sealing the edges. This way theres no physical connection to the wall to prevent this.

I was thinking either acoustic caulk, or some other caulk that stays pliable.

|

|

|

|

Post by ThomasW on Aug 21, 2009 14:21:08 GMT -7

You can pay a fortune for a caulking gun size tube of Green glue or go to your local big box store and get a tube of polyurethane caulk/sealer. Poly caulk (PL Adhesive) stays flexible when dry.

|

|

|

|

Post by jimcant on Aug 22, 2009 0:18:40 GMT -7

You and I seem to be going in opposite directions with our IB projects  Speaking from my own experience, if I were doing an array like yours, which is very similar to my first, I would have it totally decoupled from the wall. You don't have much mass or rigidity to work with, other than the floor. Start by building the array box as strong, rigid and massive as you can, at least one 3/4" layer each of both MDF and ply, or even more if you feel inclined. I would then anchor this to the floor with liquid nails and masonry bolts, at least 4 per driver cubicle. The hole in the wall for the array should be slightly oversize and the gap filled with some flexible type of sealer. This should avoid transferring mechanical movement to the walls  Now, the acoustic energy is a whole nuther ballgame, but you would already be aware of that from your current manifold IB. The only other thing you could consider, is an idea that rickp floated some time ago, for this type of installation. He suggested steel struts attached to the top of the array and bolted to the floor in a triangular configuration. The top of the array box was the thing I found the hardest to tame. I hope the above does not sound patronizing or pretentious, but I have been there and done that, and just want to give something back if I can, to a place that has given me a great deal  Cheers, Jim. |

|

|

|

Post by chrisbee on Aug 22, 2009 13:51:48 GMT -7

Or just build the complete manifold in cast concrete to start with.

An assembly using paving slabs might be possible if you can find a strong and permanent glue/cement to hold it all rigidly together. It's not just the mass you need to resist unwanted movement but the stiffness of thick concrete to limit flexure during violent cone accelerations. Which produce equal and opposite, driver reaction forces.

It is difficult to overstress the difficulty of limiting array flexure to the point where reaction forces no longer drive the building structure. Nor lose output signal as a result of the driver baskets moving the opposite way to cone movement.

Loss of signal conversion to acoustic output means reduced dynamic range and early roll off. Structural flexure means walls and other room surfaces vibrating at random frequencies in anti-phase to the driver cones. This causes jagged response curves and unwanted mechanical noise with little useful gain from using EQ. Noise also hides the reproduction of the clean fundamentals of which the IB is so uniquely capable.

Casting a concrete manifold in place might be best achieved using sacrificial polystyrene foam as cores. Once cast, the sheer weight and fragility of a green moulding would greatly increase the difficulty of moving the unit until sufficient time had passed for a reasonable cure to take place. Patience is still highly desirable no matter how the concrete is cast.

An alternative might be short lengths of pre-cast, heavy section, concrete drainage pipes. With suitably stiff driver baffles bolted on once the pipes are moved into place. A decent builders merchant with a good display of concrete drainage and paving products will provide useful inspiration.

When I had an array my entire roof would lift and creak at the start of REW test sweeps. Opposed driver manifolds offer a simple solution to driver reaction forces. As well as being remarkably compact in multi-driver IB installations.

|

|

|

|

Post by jimcant on Aug 22, 2009 20:45:42 GMT -7

Good comments there Chris, but I would like to expand on them if I may  I am probably one of the few people here that have gone to ridiculous lengths to "improve" their arrays  I guess there are two factors to consider here, mass and rigidity of support. A manifold does not really need mass as the forces are cancelled out and the box is only subject to stretch and compression, something very unlikely to occur with the recommended construction techniques. An array on the other hand does not have this, so the forces must be taken care of by anchoring to something either rigid enough or massive enough to prevent any movement that would rob or corrupt the sound, or cause unwanted side effects to the surrounding structure. In my situation, the addition of mass helped, but was still not really sufficient, in the quantity I was able to employ (about 300 lbs). I am sure a large enough amount would do the job, but I don't know how much that is  I guess what I am suggesting in my previous post, is that in this situation one wants to couple the array to most massive thing available ie the floor and in such a way that it cannot twist, as mine did originally. After my experience, I would not couple an array to a normal house structure of timber studs and sheet rock. Masonry or concrete walls are a different proposition altogether. No matter how rigid it may be, if it is hit with say, a rubber mallet, I bet you will feel vibrations in the structure, something I don't really want  I prefer all the rattles and vibrations in the listening environment to be from the acoustic energy alone ;D Arrays are awesome structures to look at, and in theory can provide the purest expression of infinite baffle bass reproduction, but dang, they are difficult beasts to implement successfully  Cheers, Jim. |

|

|

|

Post by chrisbee on Aug 22, 2009 22:01:27 GMT -7

Sorry for the confusion. I was referring to manifold in the context of this particular array design. I should have used another term or have been more specific as to my exact meaning. A boxed baffle structure, as shown in the images, could be cast in concrete or built from paving slabs. Whether it is worth the effort is another matter entirely and naturally I bow to Jim's towering expertise in this matter.  Perhaps even a concrete box is insufficiently stiff and we should consider the tetrahedron form or roof prism for constructing IB arrays where an existing block, brick or concrete wall is not available. A tilted baffle roof prism would tend to put most of the loads into the ground on which i rests. Just remember that the construction part it also supposed to be fun. So make sure that a powered concrete mixer (and a calendar) is allowed in the budget .  |

|

|

|

Post by jimcant on Aug 23, 2009 1:19:40 GMT -7

No worries there mate  You did have me a little confused by the manifold references  I was rather late getting to the party, but I am now a manifold fanboy and I have you to thank for that  Your polite but respectful badgering brought me to my senses eventually, and I am now an authority on what not to do ;D These dual manifolds are awesome and I have not heard one rattle from my shed of late. stidvr, I would think long and hard before you go down this path, whether there is any way to work around your manifolds, rather than replacing them with an array  Cheers, Jim. |

|

|

|

Post by norpus on Aug 28, 2009 7:44:34 GMT -7

Good thread. Thanks for sharing your line array theories and experinces especially. I feel enlightened  |

|

ken

Full Member

Posts: 187

|

Post by ken on Aug 28, 2009 16:11:18 GMT -7

l feel depressed lol ....... l must be the only bloke left with a lossy array  Gidday Ken , long time no see hey ...how are those beautiful octagons going ? |

|